Water and Waste Management

Waste Management, Spills, Reclamation, & Compliance

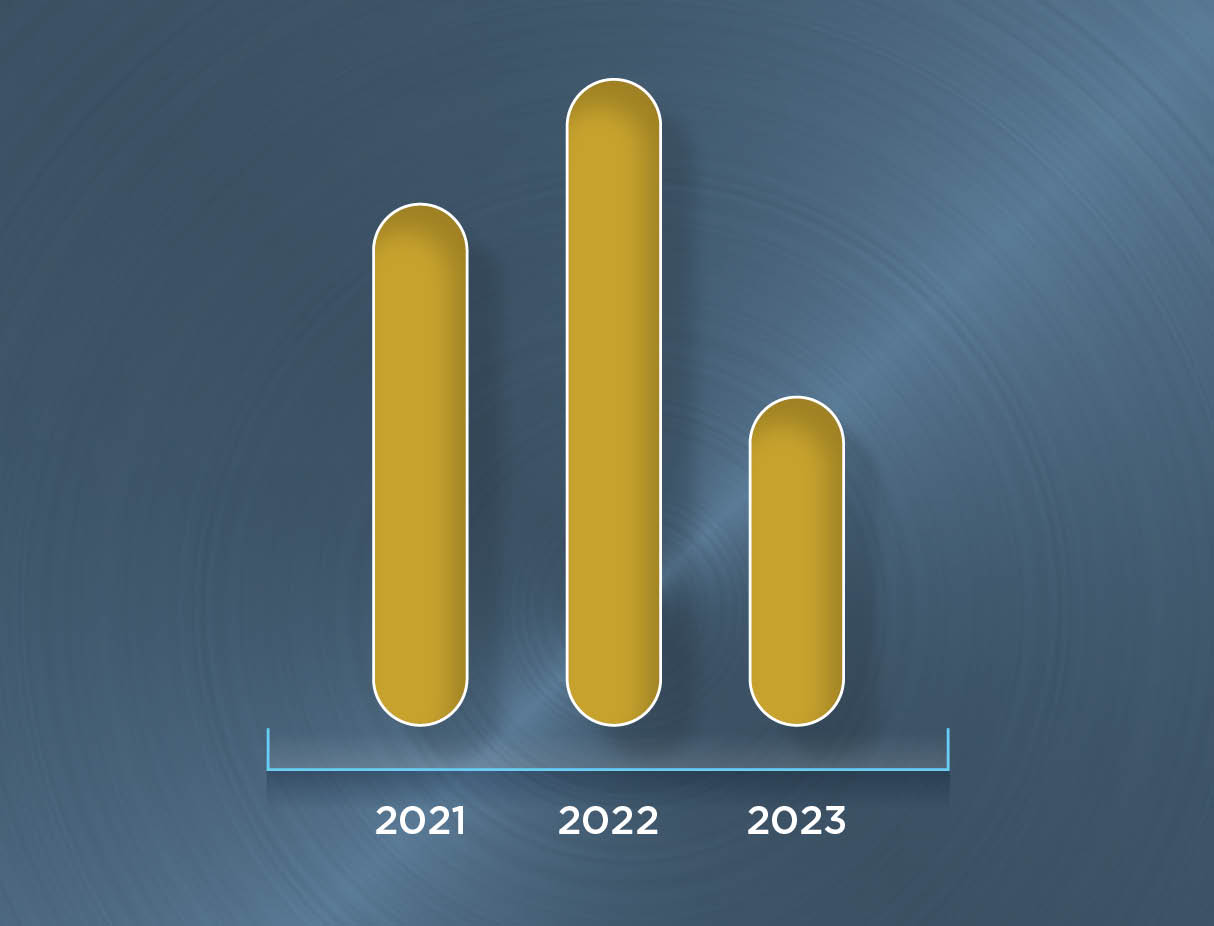

In 2021, Donlin Gold obtained permits for a new on-site landfill and a higher-capacity incinerator. The subsequent clean-up efforts, initiated in 2022, significantly contributed to an environmentally beneficial restoration of the site. With the clean-up concluded and a reduced field program in 2023, the waste volumes on-site were substantially lower. Looking ahead to 2024, there is an ongoing commitment to explore additional measures to enhance recycling levels at the site.

In 2023, the Donlin Gold project site demonstrated a commendable record of environmental compliance, with no instances of non-compliance with permit requirements. Donlin Gold has never received a citation or fine for impacts on the environment around the project site.

During the same period in 2023, no hazardous waste was generated at the site, as there was minimal drilling activity conducted in 2023. Non-hazardous waste production amounted to approximately 97 tonnes, with about 1.8 tonnes recycled, 93.6 tonnes disposed in the state-permitted on-site landfill, and the remaining portion incinerated in the state-permitted on-site facility. As a development stage company without operating mines or industrial operations in 2023, NOVAGOLD, including the Donlin Gold project, did not generate tailings, waste rock, or processing waste or wastewater. Adhering to state permit requirements, Donlin Gold undertook the stabilization of all 2023 fieldwork sites and associated access roads, successfully reclaiming a total of three acres.

During the same period in 2023, no hazardous waste was generated at the site, as there was minimal drilling activity conducted in 2023. Non-hazardous waste production amounted to approximately 97 tonnes, with about 1.8 tonnes recycled, 93.6 tonnes disposed in the state-permitted on-site landfill, and the remaining portion incinerated in the state-permitted on-site facility. As a development stage company without operating mines or industrial operations in 2023, NOVAGOLD, including the Donlin Gold project, did not generate tailings, waste rock, or processing waste or wastewater. Adhering to state permit requirements, Donlin Gold undertook the stabilization of all 2023 fieldwork sites and associated access roads, successfully reclaiming a total of three acres.

| 2021-2023 spills | |||

|---|---|---|---|

| 2021 | 2022 | 2023 | |

| Spills of 10 gallons or more to land |

0 | 0 | 0 |

The Donlin Gold project utilizes diesel, Jet A aviation fuel, gasoline, and propane for camp operations, along with minimal quantities of hazardous chemicals. Rigorous protocols ensure secure transportation and management of these substances. NOVAGOLD, consistent with its policies, sets annual environmental targets for spills at project sites. In 2023, our goal of no spills to water and no spills of ten gallons or more to land at any project sites or offices was achieved. Specifically, there were no spills requiring immediate reporting to government agencies, and all of the small spills to land were promptly and fully remediated in accordance with Donlin Gold policies, leaving no trace on or below the ground surface.

Water Management & Use

In 2023, Donlin Gold initiated a field program at the project site, which ran from February to July, completing comprehensive fieldwork and geotechnical drilling necessary for Alaska Dam Safety certification applications. This involved data collection at locations designated for water retention structures, including the proposed Tailings Storage Facility (TSF). The fieldwork comprised 1,840 meters of geotechnical drilling, 74 test pits in planned water retention structure locations, 25 kilometers of seismic survey, and TSF test plot liner installation. Additionally, 1,279 meters of hydrogeologic drilling with instrumentation and pump tests were conducted to further characterize and define groundwater conditions, providing vital information for mine planning and design. As discussed above, restoration work at the historic Lyman placer site involved significant stream and pond habitat creation.

All runoff resulting from ongoing field activities, including drill sites, is meticulously managed to uphold water quality in compliance with state permit requirements. Authorization for all water withdrawals and uses is obtained from the State of Alaska, ensuring the protection of local water resources, and preventing adverse impacts on streams and aquatic life.

The current camp relies on groundwater wells for its domestic water supply, while sanitary wastewater undergoes treatment in a leach field, allowing for recycling to the subsurface. As of 2024, the environmental risk posed by current camp septic wastewater and waste management activities is minimal, given that the site is not an operational mine and it continued to not generate industrial waste or wastewater.

Primary water-related risks are associated with the Donlin Gold Project, which are anticipated to become material when the full-scale project enters large-scale construction and operation. As stated above, present operations are minimal and, therefore, carry negligible risk. The Donlin Gold project has been carefully designed to prevent uncontrolled discharge of mine-contacted water. Any water in contact with mine facilities would be utilized in the milling process to the maximum extent feasible or treated and discharged in accordance with stringent permit standards.

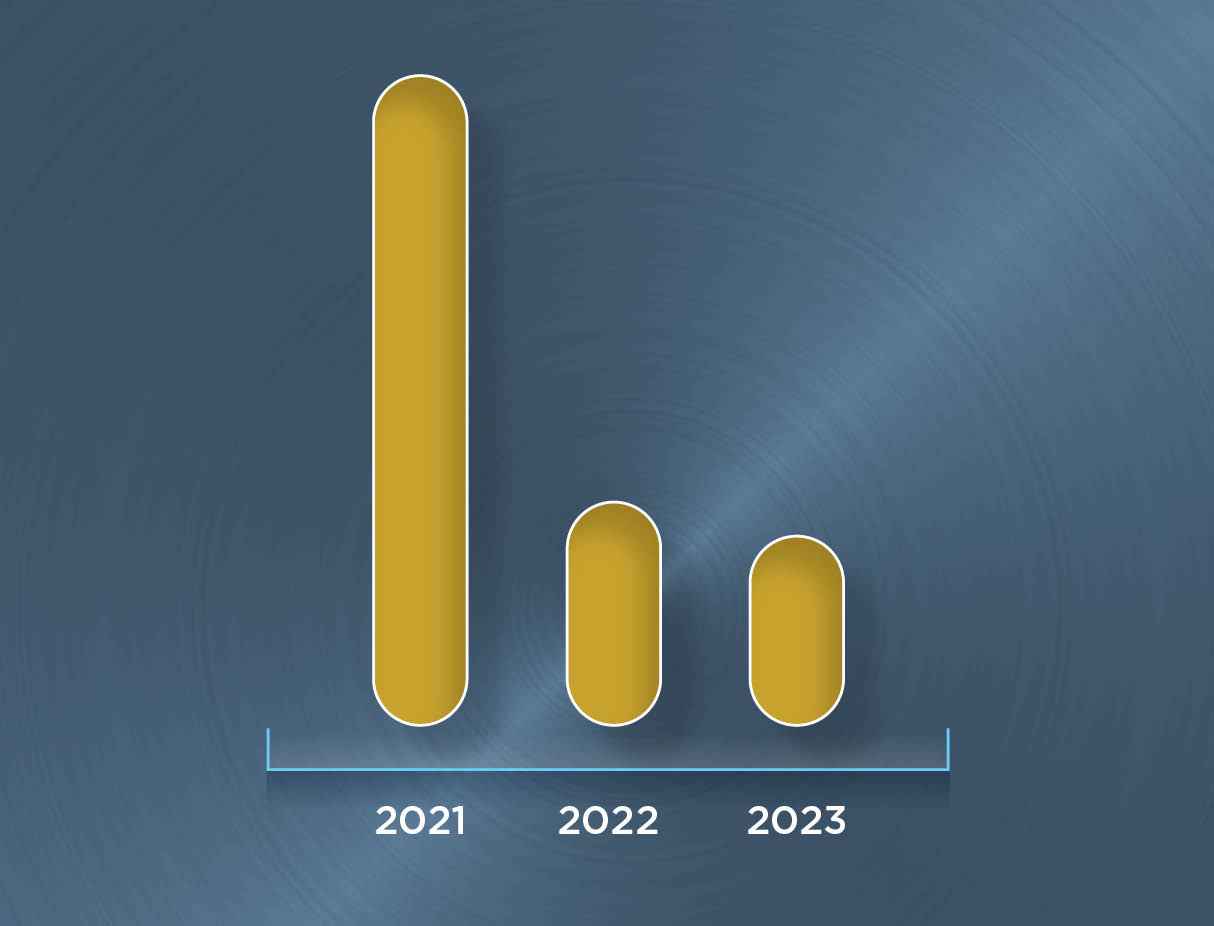

Donlin Gold used approximately 282,276 gallons of ground water to support camp operations during 2023. This reflects the small field program in 2023 compared to 2022 (approximately 549,478 gallons were used in 2022). With site’s current minimal water uses and abundant supplies in the region, water scarcity is not a current concern.

Like the low but variable GHG emissions, water use at the project site changes on an annual basis depending on camp needs such as domestic supply, core cutting, and equipment and facility washdowns. With again expected limited field activity in 2024, it is projected that the camp water use volume will remain relatively similar. In addition, all water withdrawals and uses are authorized by the State of Alaska. The permitting process provides for protection of other local water uses, including ensuring no adverse impacts to streams and aquatic life. Finally, as noted previously, the plans for the full-scale mine operation maximize re-use to limit water supply needs.

NOVAGOLD’s offices in Vancouver and Salt Lake City combine used approximately 87,000 gallons of water in 2023, all drawn from municipal water systems and largely recycled back to the environment (minus minimal losses for personal consumption). Between the Donlin gold project and NOVAGOLD about 370,000 were used in 2023, a notable decrease from 2022, which was primarily the result of a smaller field program during 2023. Essentially all water used was recycled to the environment.

* Groundwater is related to Donlin Gold and surface water is related to NOVAGOLD Salt Lake City and Vancouver Corporate offices